Cable recall goes slow while risks rise

Thousands of Australian homes and businesses have faulty electrical cabling posing a serious danger, and the Australian Competition and Consumer Commission has warned time is running out to get it fixed.

Thousands of Australian homes and businesses have faulty electrical cabling posing a serious danger, and the Australian Competition and Consumer Commission has warned time is running out to get it fixed.

The ACCC launched a massive recall in 2014, after it was revealed that a particular type of electrical cable - sold in Australia by the brands Infinity and Olsent – was too brittle and able to degrade, causing fires or electric shocks.

Experts have warned that problems from the degrading cables are expected to start as early as 2016.

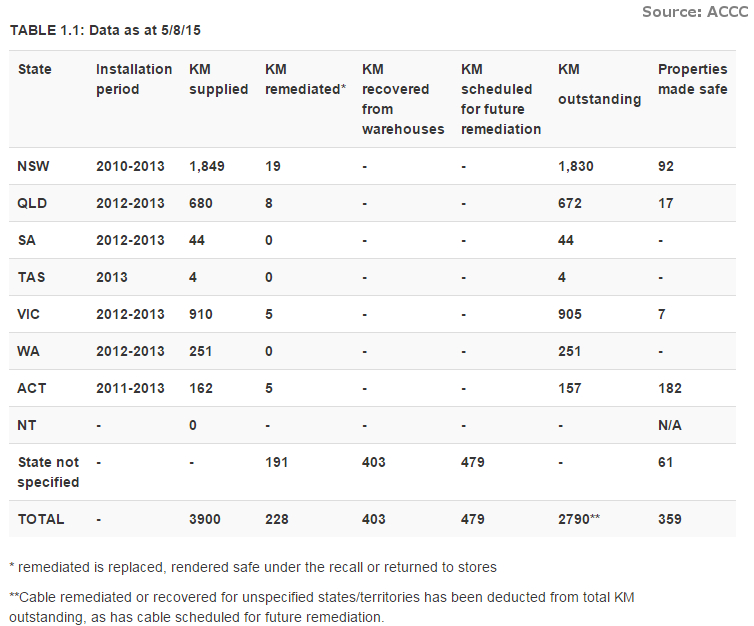

An estimated 3,900 km of unsafe cable was supplied, but over 2,800 km is yet to be remediated, recovered or scheduled for remediation under the recall. Just 28 per cent of the cable has been accounted for.

“The ACCC is extremely concerned that over 70 per cent of the cable supplied has not been accounted for under the recall,” ACCC Deputy Chair Delia Rickard said.

The ACCC is this week holding an Infinity Regulatory Taskforce meeting with Electrical, Building and Australian Consumer Law regulators to discuss and agree what more is needed from businesses on this front.

“It is clear that all businesses in the supply chain need to be doing more to alert consumers to the recall and remediation options.”

“The ACCC is urging electricians, builders, and contractors to notify their customers and cable suppliers if they installed Infinity cables between 2010 and 2013,” Ms Rickard said.

The ACCC recently undertook an advertising campaign to warn consumers about the risks of Infinity cables.

“Consumers that purchased new properties, undertook renovations, had appliances installed or had electrical work carried out in the past few years should contact a licensed electrician for a safety inspection to determine if Infinity cables were installed,” Ms Rickard said.

“Consumers should not attempt to inspect cables themselves. Any affected cable installed in accessible areas or near heat sources must be removed and replaced under the safety recall.”

Infinity cables were recalled last year after they failed electrical safety standards due to poor quality plastic insulation coating, which will become brittle prematurely.

Once the insulation is brittle, physical contact with the cables could dislodge the insulation and lead to electric shock or possibly fires.

The risk of physical contact is highest in roof spaces and under raised floors, as cables exposed to prolonged high temperatures will degrade at a faster rate.

The following table shows the progress made so far:

Print

Print